Product Function

LFS(Liquid Food Solution) is dedicated to be a global comprehensive liquid food packaging provider.

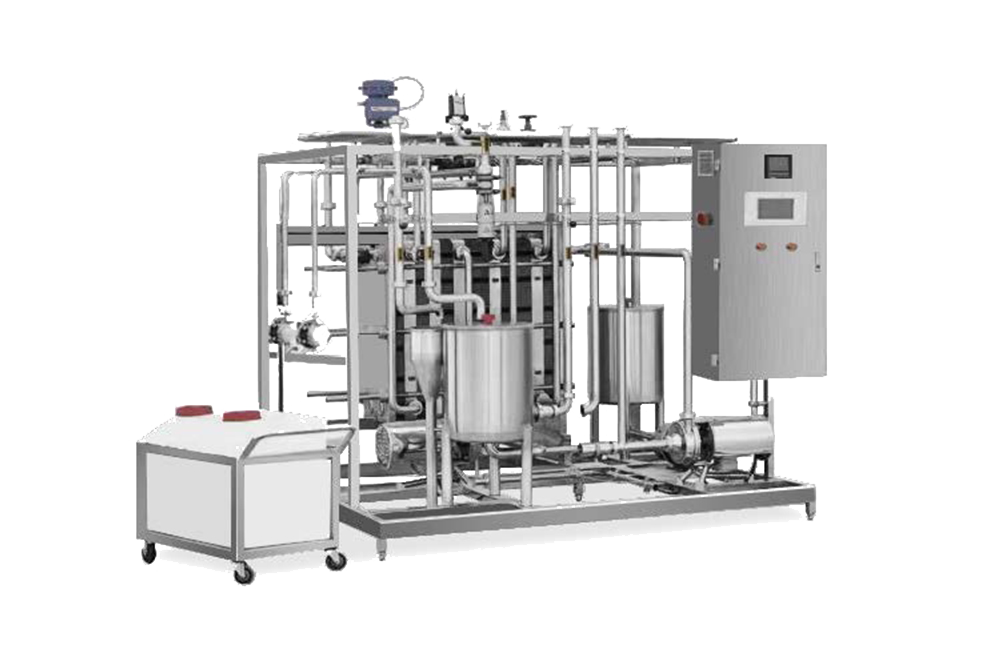

Automatic systems for heat treatment

Tubular UHT sterilizers are widely used in liquid food "aseptic" and "non-sterile", fully automatic systems for heat treatment, with a wide range of product viscosity and adaptability to fibers and particles.

High precision product/water temperature difference control

The product is pumped from the balance tank, preheated to the homogenization temperature, and then preheated to 90~95℃ , the temperature of the milk protein is carried out, then ultra-high temperature sterilization, and finally cooled to the filling temperature.

Saving energy

Pre-sterilization with hot water in the system is in the circulation loop. Tube diameter, shape (straight or corrugated) and tube bundle only 4 O-rings (on the media end only) are required for each set of heat exchangers and only need to be inspected once a year.

Economical processing method

The economical processing method can use a semi-automatic unit, which also obtains the same effect.

Specifications

LFS(Liquid Food Solution) is dedicated to be a global comprehensive liquid food packaging provider.

- Capacity

1000 - 40000 l/h

- Automation with PLC

Flow rate, Temperature, Pressure, PH

- Precise control of sterilization temperature

± 1℃

- Heat recovery

up to 95%

- Aseptic Process

5℃ → 65℃(Homo) → 95-139℃(5-30S) → 20-25℃

- Hot Filling Process

5℃ → 65℃(Homo) → 95-139℃(5-30S) → 85-90℃

Product Advantages

LFS(Liquid Food Solution) is dedicated to be a global comprehensive liquid food packaging provider.

Product Application

LFS(Liquid Food Solution) is dedicated to be a global comprehensive liquid food packaging provider.