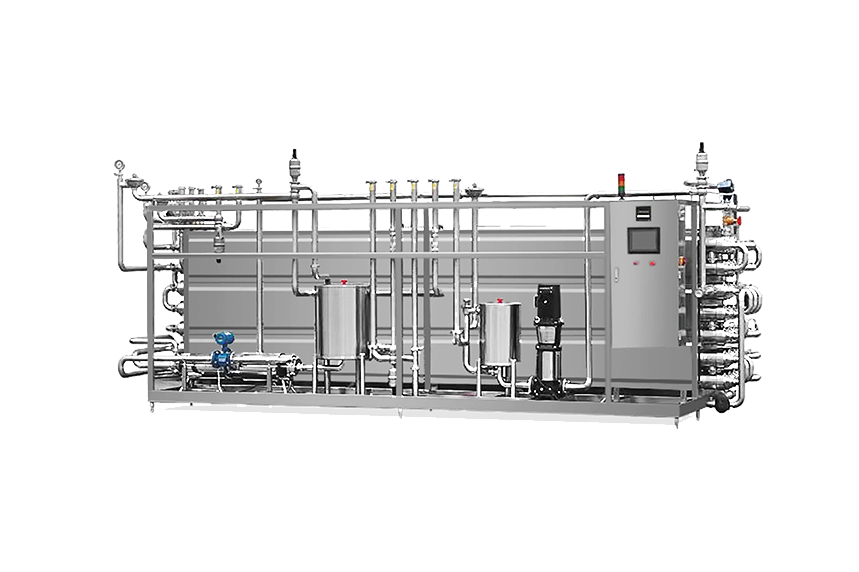

HTST Sterilization Unit

Product Advantages

LFS(Liquid Food Solution) is dedicated to be a global comprehensive liquid food packaging provider.

-

Ultra-pasteurization

Instantaneous sterilization is between pasteurization and ultra-high temperature sterilization, also known as ultra-pasteurization, and the temperature is around 120℃ ~125℃ . It belongs to the category of non-sterile state, and the bacteria have been basically killed. -

Filled cleanly

It can be filled cleanly and can be stored for 7~30 days under refrigerated conditions of ≤ 7℃ . It is a popular sterilization equipment. -

Widely used

It is mainly filled with fresh-keeping milk and soy milk at low temperature. Acidic juice and tea beverages can be filled at high temperature and kept fresh at room temperature and can be filled at low temperature and kept fresh at refrigeration. -

Maximize the nutritional content

Fresh high-acid juice beverages generally use a lower temperature of 95~105 ° C, in order to maximize the nutritional content of the juice and enjoy the natural juice flavor.

Related Products

LFS(Liquid Food Solution) is dedicated to be a global comprehensive liquid food packaging provider.

-

UHT

Widely applied to aseptic & non-sterile liquid food automatic heat treatment systems, adaptable to various product viscosities, fibers and particles. -

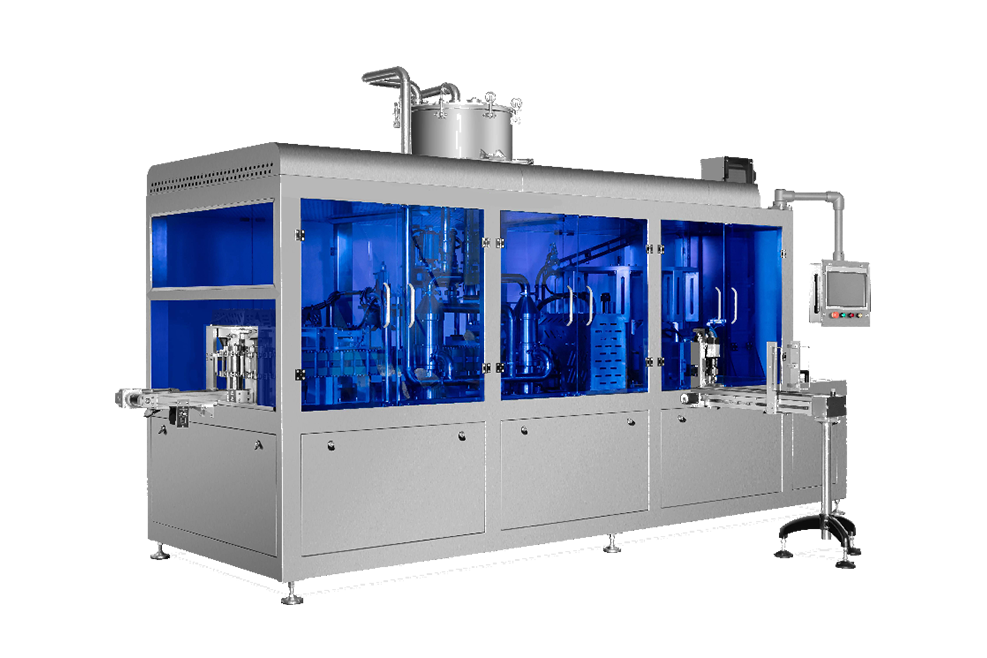

Filling Machine for Gable Top

Enables convenient and efficient setup, features a low failure rate, offers high cost-performance with customizability. -

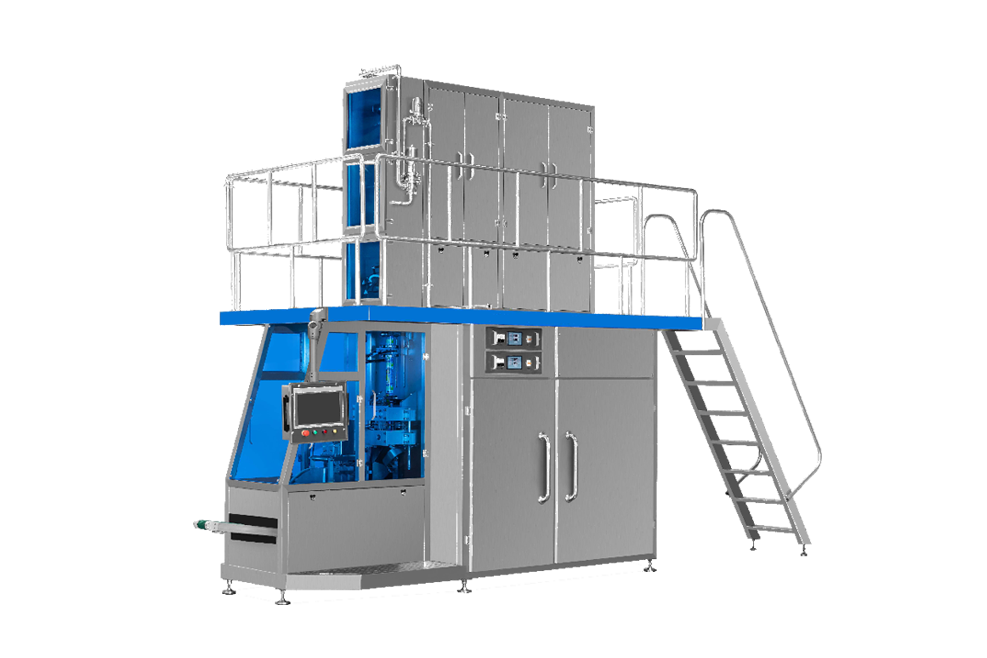

Aseptic Filling Machine for Brick Package

Enables convenient and efficient setup, features a low failure rate, offers high cost-performance with customizability. -

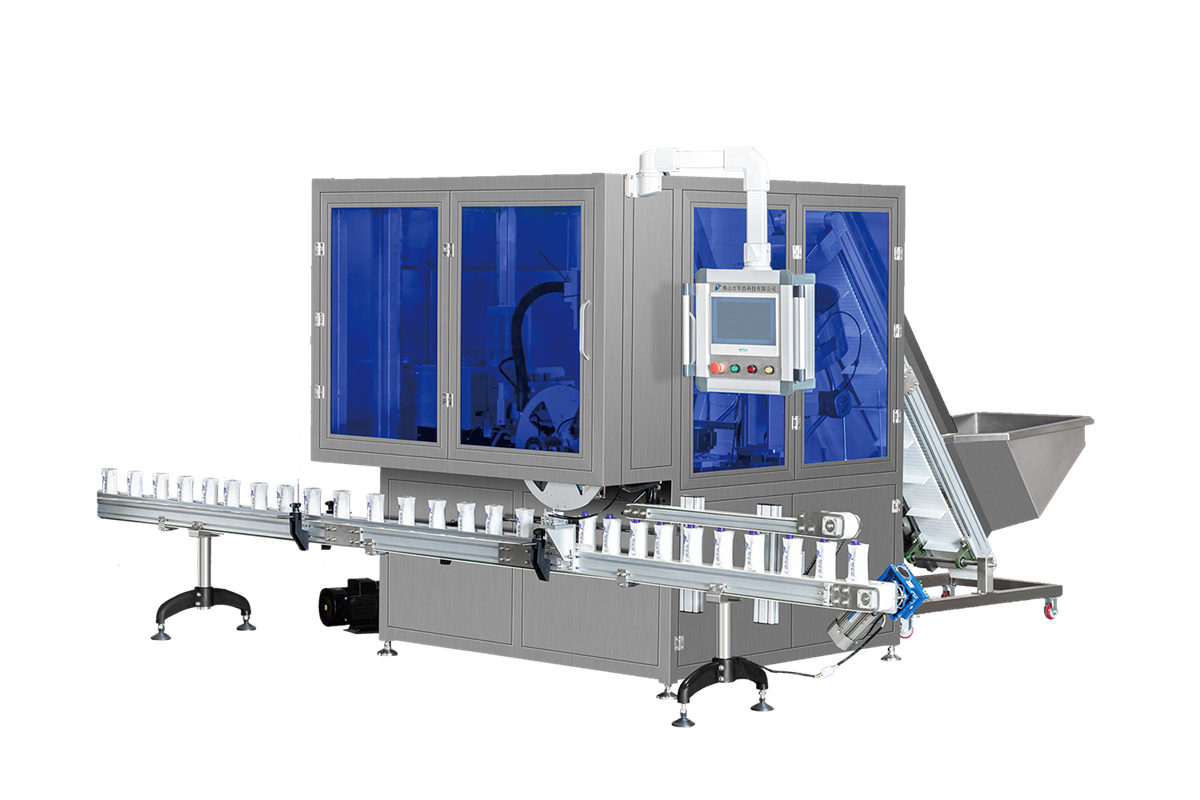

Cap Applicator

Seamlessly integrable with existing lines, with industry-exclusive patented dispensing robotic arm and adaptive lid-sealing actuator.