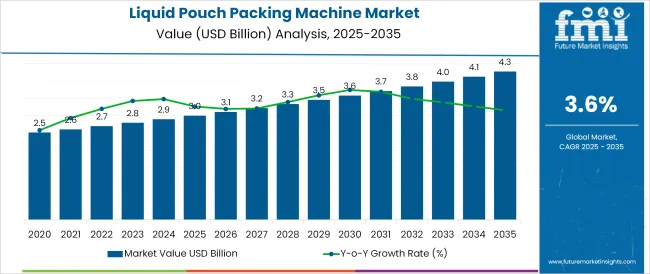

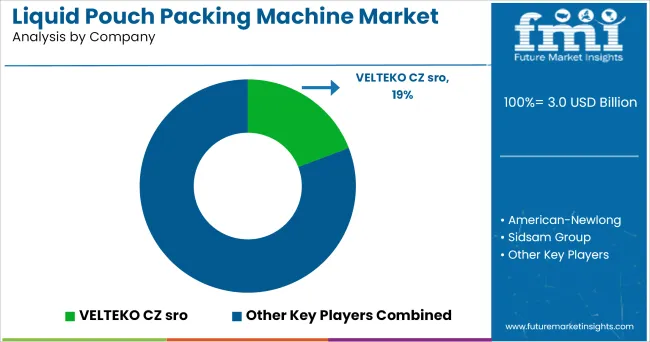

The Liquid Pouch Packing Machine Market is estimated to be valued at USD 3.0 billion in 2025 and is projected to reach USD 4.3 billion by 2035, registering a compound annual growth rate (CAGR) of 3.6% over the forecast period.

Quick Stats for Liquid Pouch Packing Machine Market

Industry Value (2025): USD 3.0 billion

Forecast Value (2035): USD 4.3 billion

Forecast CAGR: 3.6%

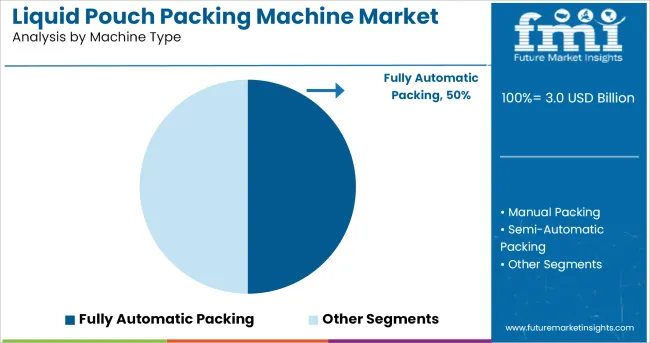

Leading Segment in 2025: Fully Automatic Packing (50.0%)

Key Growth Region: North America, Asia-Pacific, Europe

Top Key Players: VELTEKO CZ sro, American-Newlong, Sidsam Group, Suvi Packaging Machines, Holweg Weber, Others

| Rationale for Segmental Growth in the Liquid Pouch Packing Machine Market

Market Overview

The liquid pouch packing machine market is undergoing dynamic growth, shaped by the rising consumption of packaged liquids, advancements in packaging automation, and growing hygiene and efficiency standards in production environments. The shift from rigid containers to flexible pouch formats, motivated by lower logistics costs and improved shelf visibility, is reinforcing the adoption of high-performance pouch filling systems.

Governmental emphasis on food safety compliance, sustainability in packaging, and automation of manufacturing operations has positioned liquid pouch machinery as a critical asset in modern production lines. Technological innovations in sealing precision, leak detection, and viscosity management are enabling broader application of these machines across food, beverage, pharmaceutical, and chemical industries.

In the coming years, further growth is anticipated from increased penetration in developing regions, where small-to-mid-size enterprises are embracing automation to enhance product consistency and reduce operational downtime. The integration of smart controls, clean-in-place (CIP) systems, and modular upgrades will further accelerate deployment and life-cycle value.

| Segmental Analysis

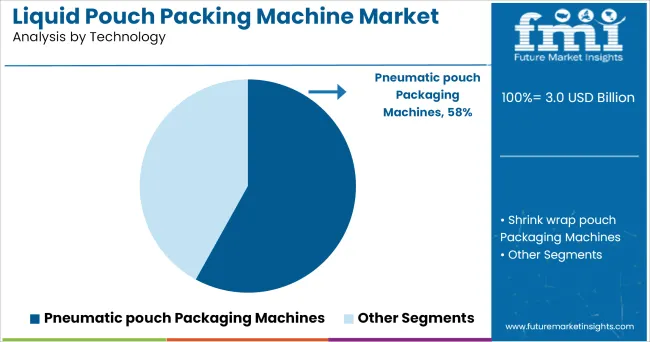

The market is segmented by Machine Type, Technology, and End-User and region. By Machine Type, the market is divided into Fully Automatic Packing, Manual Packing, and Semi-Automatic Packing. In terms of Technology, the market is classified into Pneumatic pouch Packaging Machines and Shrink wrap pouch Packaging Machines.

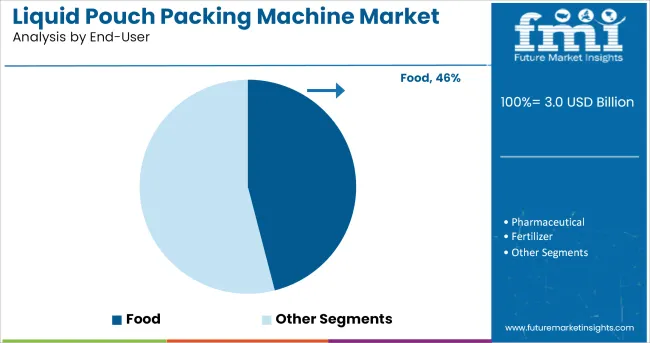

Based on End-User, the market is segmented into Food, Pharmaceutical, Fertilizer, Cosmetic, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Insights into the Fully Automatic Machine Type Segment

By machine type, fully automatic liquid pouch packing machines are projected to contribute 50% of market revenue in 2025, establishing them as the leading segment. This dominance is being driven by the ability of fully automatic systems to deliver high-speed, low-error packaging with minimal human intervention, significantly improving productivity in high-demand environments.

The use of programmable logic controls, servo systems, and integrated sensor arrays enables real-time monitoring and adjustment, resulting in consistent pouch filling, reduced wastage, and extended equipment uptime. These systems have become essential in industries where contamination control, output precision, and production scalability are non-negotiable.

Their compact footprint, combined with energy-efficient motors and automated material handling, supports lean manufacturing objectives while enhancing operator safety. As labor costs rise and regulatory oversight intensifies, fully automatic machines are increasingly viewed as strategic investments that ensure regulatory compliance, enhance throughput, and deliver measurable operational efficiencies across large and mid-scale enterprises.

Insights into the Pneumatic Technology Segment

From a technology standpoint, pneumatic pouch packaging machines are expected to capture 58% of market revenue in 2025, driven by their reliability, cost efficiency, and low maintenance requirements. Pneumatic systems offer precise control over filling and sealing operations, especially in environments handling varying viscosities and temperature-sensitive liquids.

The simplicity of pneumatic actuation reduces the risk of mechanical failure, while maintaining high cycle speeds and clean operation, making them ideal for sterile and semi-sterile packaging settings. The absence of complex electrical systems lowers downtime, and their adaptability to different pouch types has broadened use cases across small-to-medium enterprises.

Pneumatic systems are particularly effective in regulated industries, as they meet stringent hygiene and cleaning protocols. With enhanced compatibility for integration into semi- and fully-automated production lines, their use is being supported by an increasing number of OEMs offering modular platforms. The scalability, durability, and ease of integration of pneumatic technologies are key contributors to their continued market leadership.

Insights into the Food End-User Segment

By end-user, the food industry is projected to hold a leading 46% share of the liquid pouch packing machine market in 2025, reflecting its deep reliance on precise, sanitary, and high-throughput packaging solutions. This dominance is underpinned by increasing demand for single-serve, ready-to-eat, and extended shelf-life liquid products such as sauces, dairy, soups, and health beverages.

Food producers are prioritizing machinery that ensures product integrity, prevents microbial contamination, and supports a variety of pouch materials suitable for cold-chain and ambient storage. The ability of liquid pouch packing machines to accommodate flexible fill volumes and offer hermetic sealing has enabled compliance with food safety regulations while optimizing line efficiency.

Additionally, growing consumption in urban centers, combined with rising expectations for packaging convenience and portion control, has accelerated the adoption of advanced pouch solutions. As sustainability goals reshape packaging strategies, the food sector is increasingly turning to high-speed, precision-driven machines that can deliver performance, flexibility, and compliance in one integrated system.

| What is Driving Demand for Liquid Pouch Packing Machine?

There is an increase in demand for minimizing human errors and increasing efficiency in different industries with the help of computers. This is one of the major factors fueling the growth of liquid pouch packing machines. There are industries such as food, beverage, and pharmaceutical, they want them free from any contamination.

They are continuously working on automatic filling machine to make sure that there is no human touch. This will also fuel the growth of liquid pouch packing machines in upcoming years.

Due to drastic changes in consumers' buying habits with new technology and trends, this too will contribute to the market growth. The packing machine is becoming a cost-effective solution for both manufacturers and consumers.

As customers are getting health conscious day by day, they look for healthy packing pouches. In such a scenario, healthy liquid packing pouches are fulfilling their needs and this need is creating many opportunities for market growth. The pouches are small, easy to carry, easy to use, and convenient to dispose of. This is further helping the market of liquid pouch packing machines to grow globally.

| What are the Key Trends for Liquid Pouch Packing Machine?

There is a rise in the rapid rate of the pharmaceutical industry with new research and developments. There is a huge investment from pharmaceutical drug manufacturers to develop drugs to broaden the variety of products in their product offerings, this will drive the growth for liquid pouch packing machines.

As there are many R & D projects are going on in medical sciences for advanced machinery for bulk drug production, processing, and packaging, this too is generating huge opportunities for the liquid pouch packing machine market globally.

For an instance in 2020, Cambrex Corporation, a Canada-based company announced that it will double its capacity of the liquid packaging and weekly output at its Mirabel site in Canada. The company will also add a new filler on the existing packaging line and a CGMP (Current Good Manufacturing Practice) packaging line. Such trends are driving the growth of liquid pouch packing machines globally.

| South Asia Demand Outlook for Liquid Pouch Packing Machine

South Asia is becoming one of the advanced regions for manufacturing liquid pouch packing machines for many key vendors with the help of advanced technology as the labor is cheap. The government is also supporting the development of new industries, working in this area of the solution.

It has been found that South Asia people are strongly supporting environment-friendly packing and also demanding skincare and particularly luxury products. Such penetration will create many opportunities for liquid pouch packing machines in coming years in this region.

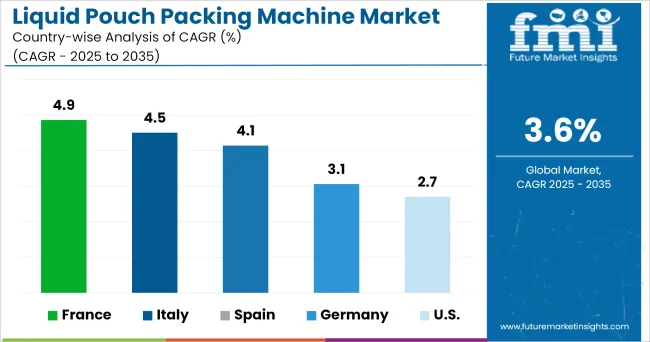

| Europe Demand Outlook for Liquid Pouch Packing Machine

The European region is going to hold a significant share of the liquid pouch packing machine market from 2024 to 2035. The reason behind this the presence of major solution providers in the region.

Europe region is having the largest market for pouch packaging machines in the food and beverage industries. Hence, due to extended boundaries of flexible packaging in food, beverage, and medical applications, the demand for liquid pouch packing machines continues to grow in this region.

| Who are the Key Liquid Pouch Packing Machine Vendors?

Some of the leading vendors of liquid pouch packing machines include

VELTEKO CZ sro

American-Newlong

Sidsam Group

Suvi Packaging Machines

Holweg Weber

Others

Some of the key players in the liquid pouch packing machine market and they are actively involved in offering liquid pouch packing machine solutions for different applications.